OUR WORLD REVOLVES AROUND YOU

Induction Hardening

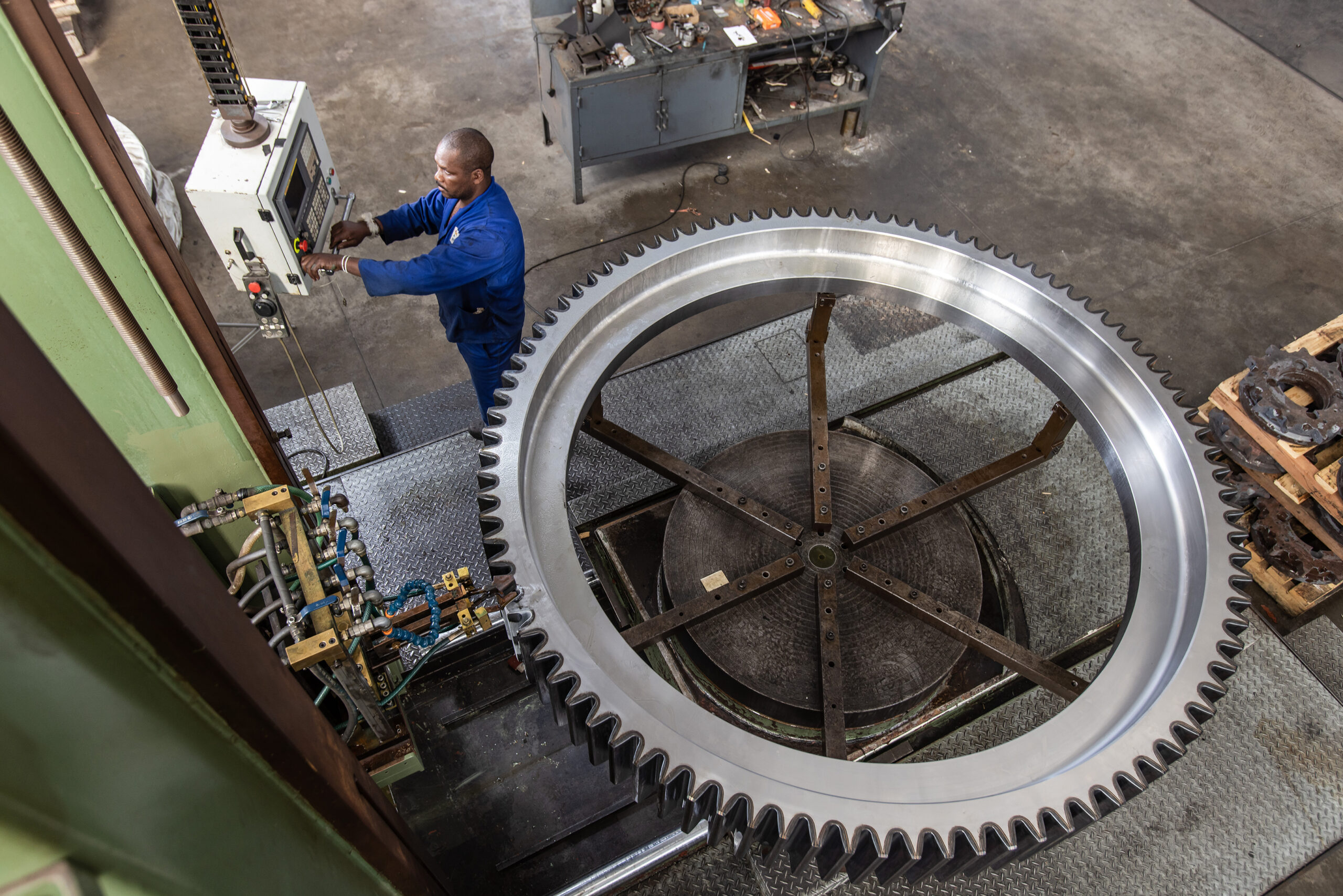

Automated process control

Induction hardening - high throughput capacity, CNC control

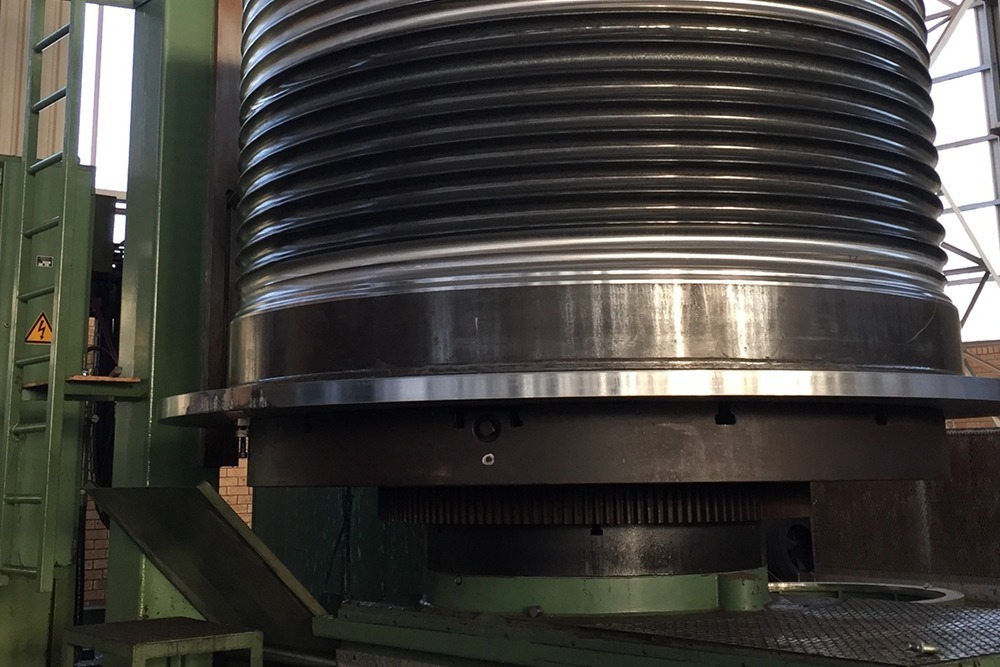

Titanus Slew Rings (TSR) offers both internal and external diameter induction hardening services. We have the largest operational platform of induction hardening facilities on the African continent comprising three CNC controlled, medium frequency, induction hardening plants.

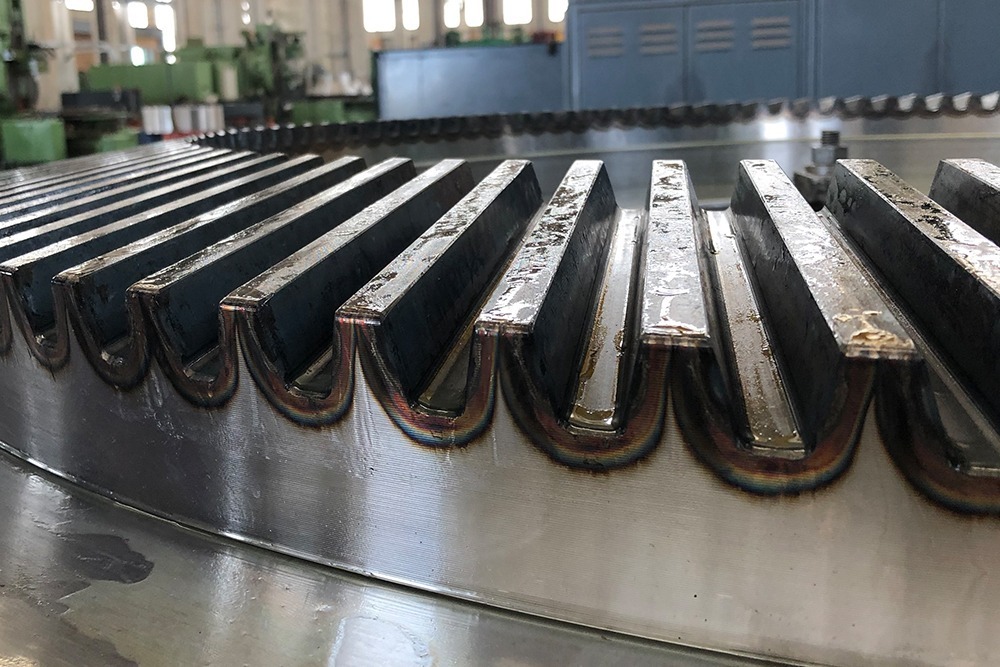

We process bearing raceways, pins, axles, gear teeth and rope grooves. Induction hardening achieves high hardness to a controlled surface depth, typically around 3-8 mm deep, providing gear teeth with increased resistance to pitting and corrosion due to atmospheric contaminants. We offer services for small or large volumes of material and can provide a full data pack and certification.

Titanus undertakes induction hardening for the following:

- Spur, helical & bevel ring & pinion gears

- Sprockets

- Splined drive shafts

- Pins & bushes

- Chain links and side plates

- Winch and Sheave rope grooves

- Riding ring, bogie & crane wheels